General

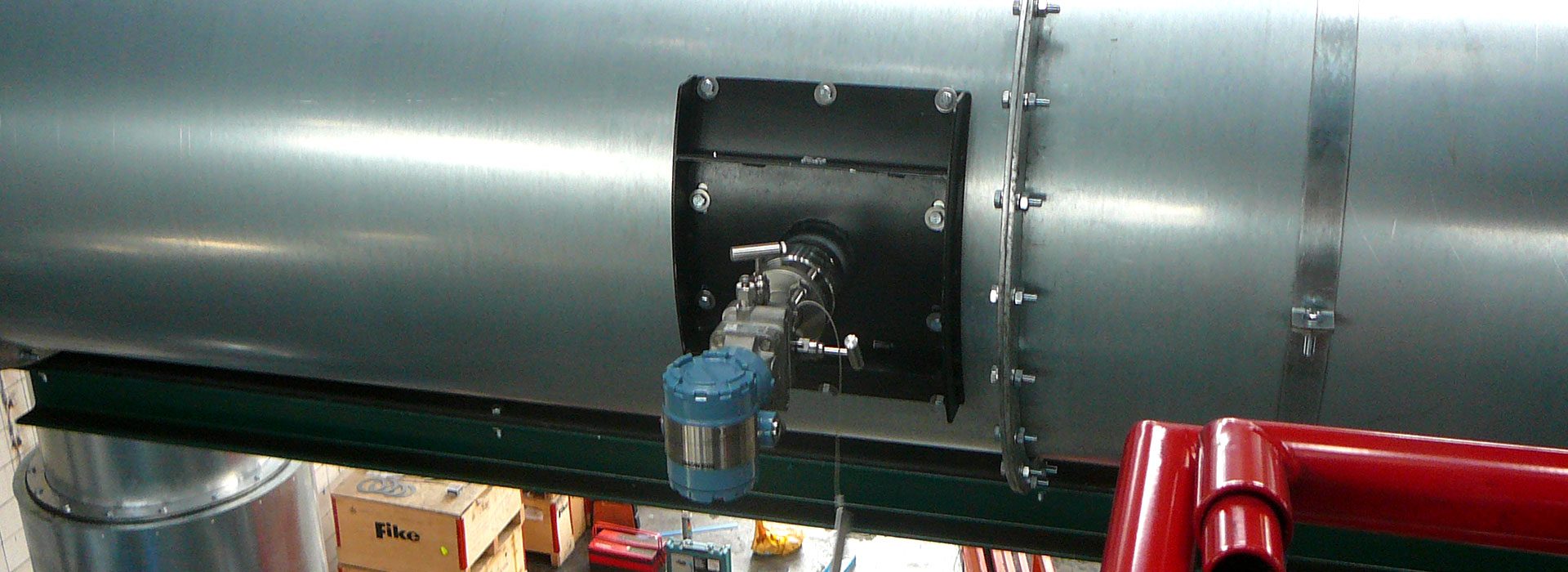

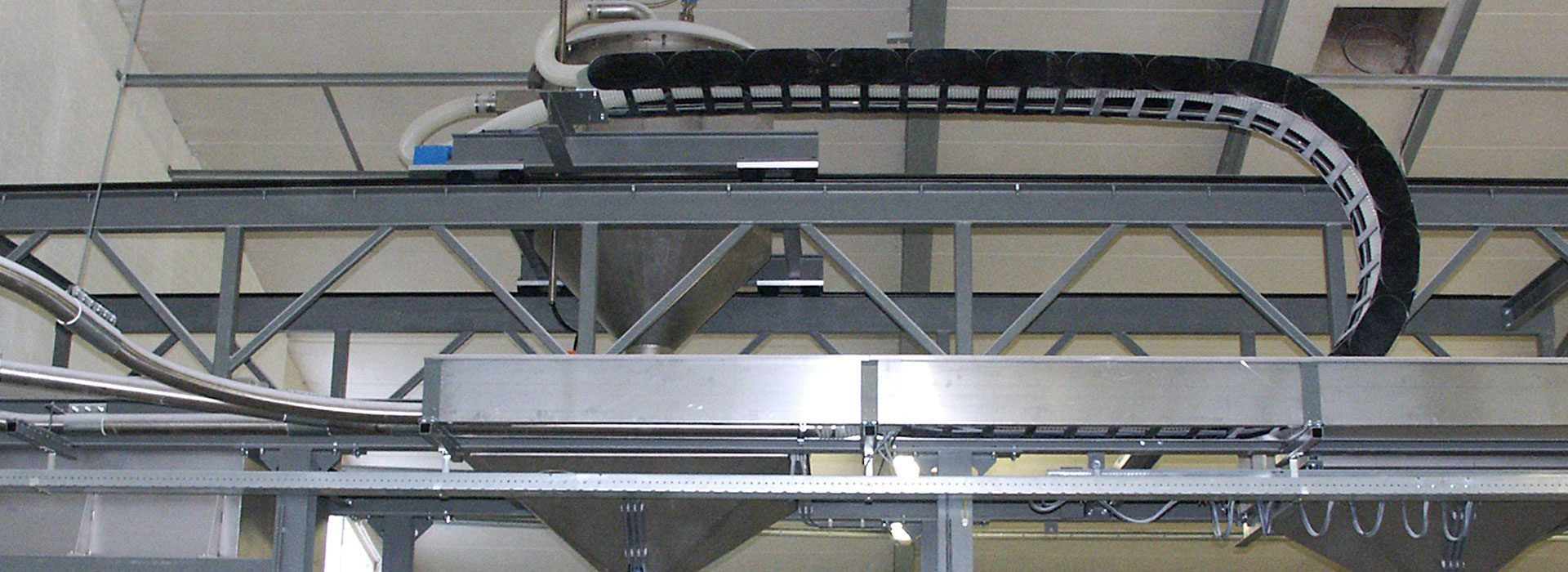

MACBuster® sucks in contaminated air on one side and blows the clean air out on the other side. The sucked and blown air flows are directed such that they do not interfere with one another. For proper operation of the MACBuster®, disturbances of the air flows created in this manner must be avoided. Heating systems based on radiation are best suited for this system.

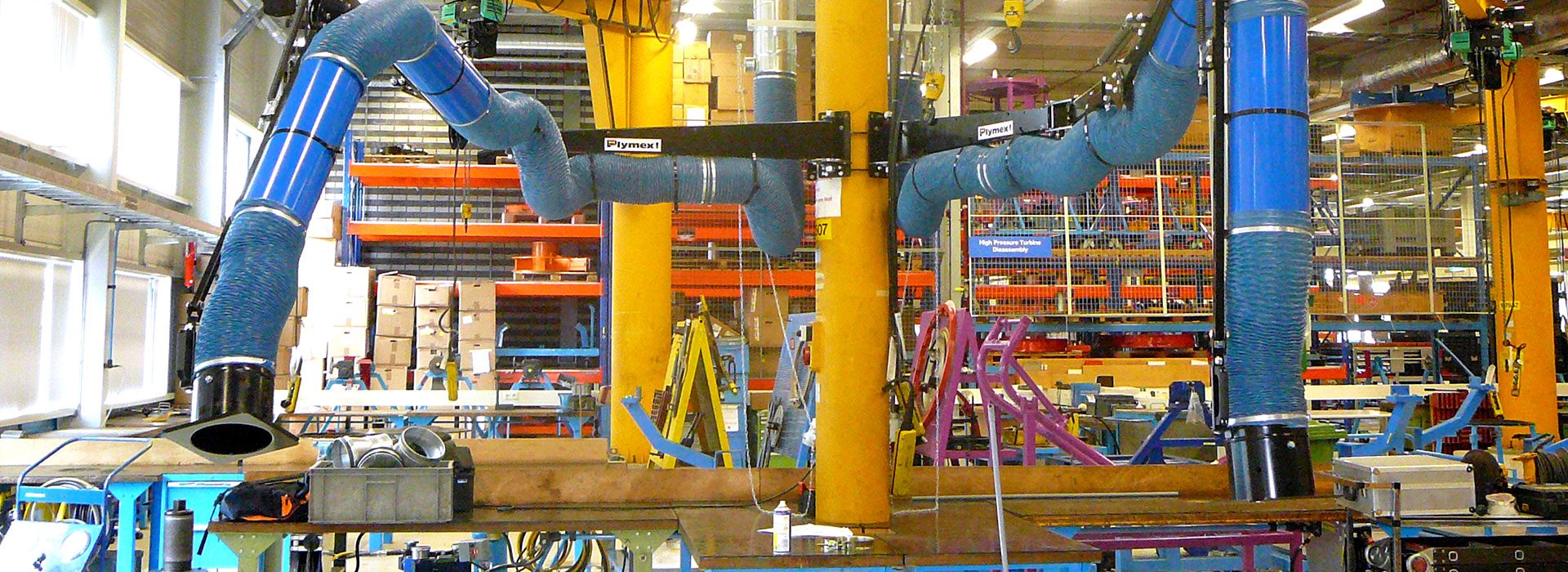

Besides being the perfect solution in spatial ventilation, the MACBuster® is also suitable for permanent connection to one or more existing exhaust installations, such as one or more exhaust hoods for welding vapours. The numbers of installations naturally depend on the capacity of the selected MACBuster®. The MACBuster® can be placed and/or suspended in almost any existing hall.

Contact us thru the button below for more information, or a complete obligation free offer.

Combine the MACBuster® dedusting installation with Pender Vario radiation heating for a perfect climate control system!

Types and Dimensions

- MACBuster®-1 / -12: depending on the amount of air to be processed, 1 to a maximum of 12 filter elements.

- Dimensions: depending on the number of filter elements and ventilator size, from about 2 x 1.50 x 1.35 m.

Merits

The purchase of a MACBuster® is usually eligible for EIA (energy investment deduction), VAMIL depreciation (accelerated depreciation for investments in environmental-friendly equipment) and MIA (environmental investment deduction).

U.C. Technologies will be happy to take care of your application, if desired.

Key Points

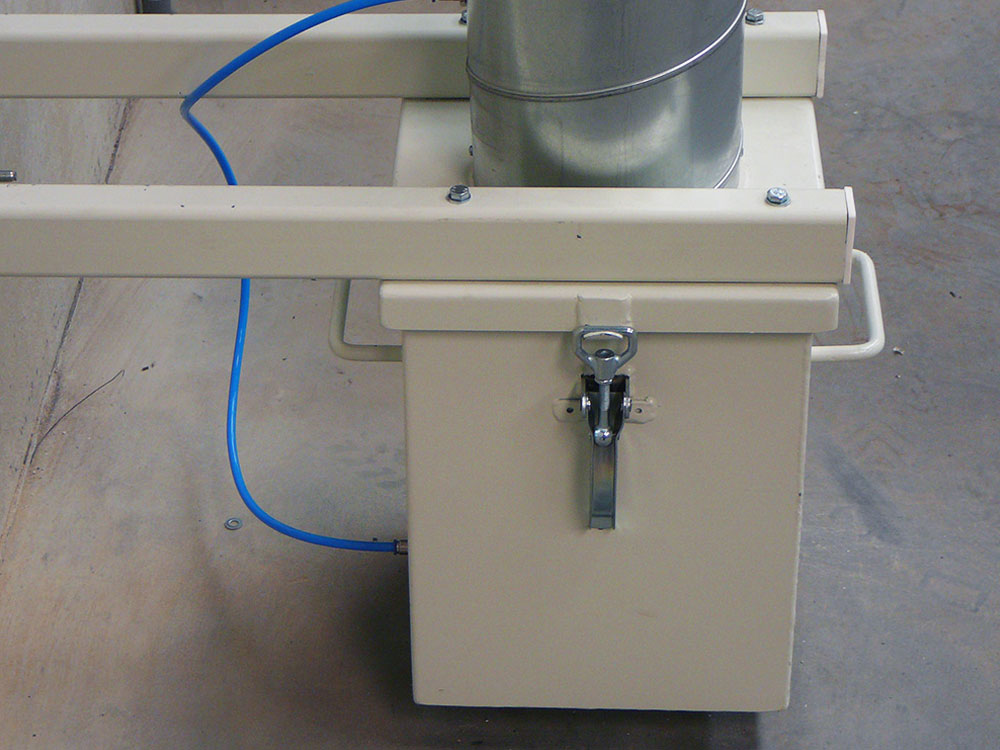

- Compact and modular dedusting installation with one or more filter cartridges.

- Dedusts the sucked air and blows it back into the hall, supplemented with ambient air.

- Very suited for halls with a high dust content (caused by welding, cutting or grinding, for example), where local exhaust is not possible or not desired.

- MACBuster® is also suitable for connection to one or more existing exhaust installations.

- Recirculation of the filtered air is permitted (in contrast to dedusting the air with electrostatic filters).

- Recirculation of the air realises a considerable reduction of heat loss.

- Filter cartridges made of filter cloth are treated with Ultra Web. Ultra Web is a surface treatment with microscopically small fibres for maximum filter efficiency.

- Efficiency of filter cartridges is 99.9% with dust particles of 0.3 micron and larger.

- Automatically controlled compressed air cleaning system.

- Good possibility of maintenance through the accessibility and fast exchange time of the cartridges.

- Standard pressure difference meter for control of the resistance across the cartridges as well as the control unit with control printed circuit board. Sound insulation.

- Standard colours: RAL 5015/6011/7035. The installation can also be supplied in any other desired RAL colour.

- CE-certified, name protected.