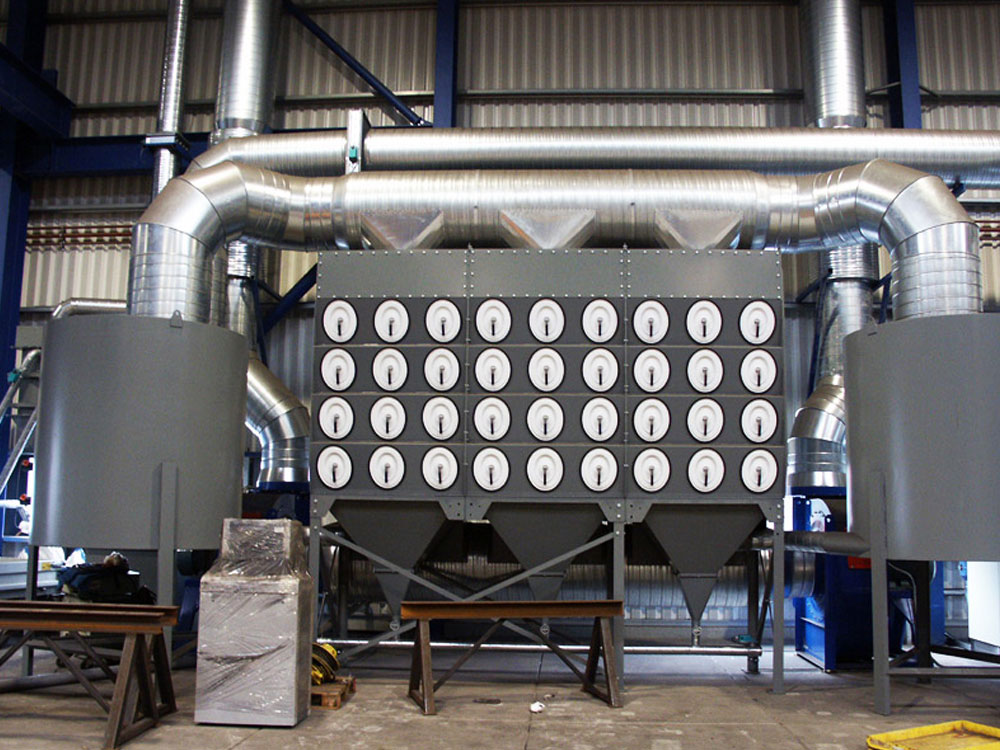

General

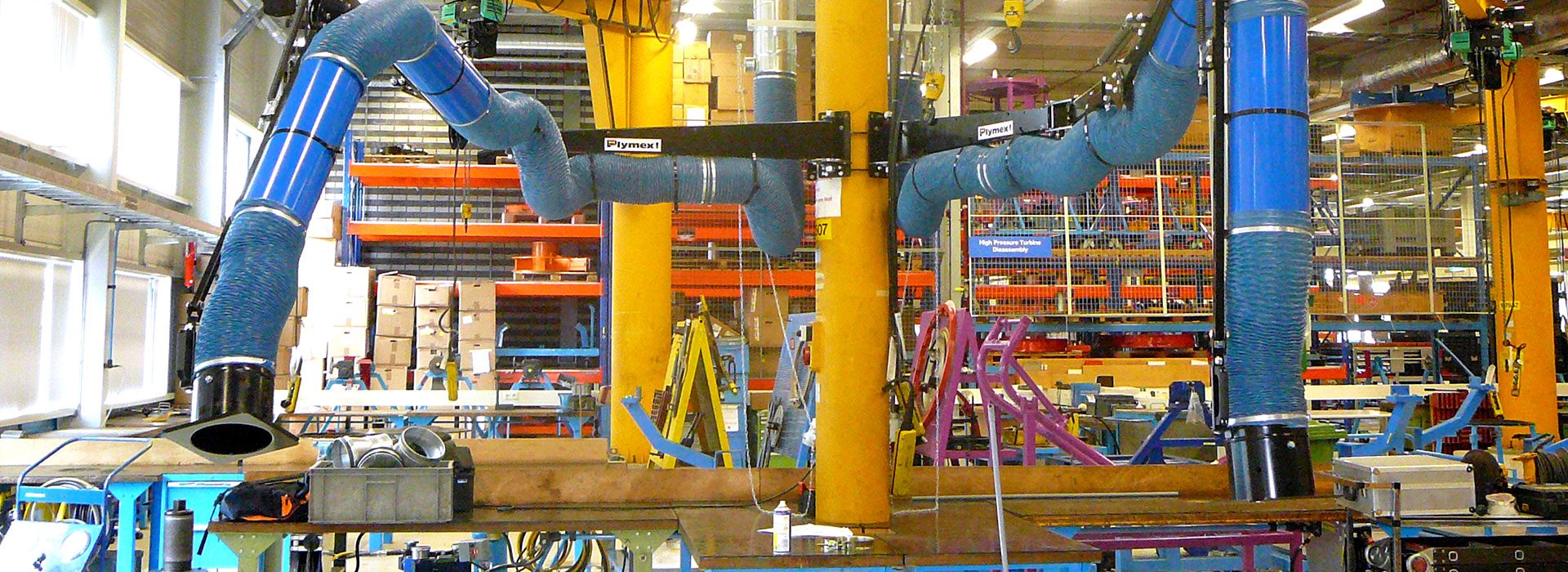

The basic section is made up of extraction segments of 3 to 5 mm sheet divided into two chambers. While in operation, 2 chambers at the most are extracted simultaneously. The extraction power is distributed across the full width of the table.

Pneumatic control modules ensure thorough venting of polluted air through valves located at the side of the table. The polluted air is exhausted laterally to the discharge duct. The design guarantees a minimum loss of extraction power during closing of a valve and activation of the following.

Contact us thru the button below for more information, or a complete obligation free offer.

Cooling

The NOVODEK® is patented because of its attractive features with regard to capture efficiency and internal cooling. As an option, the NOVODEK® can provide the deck and inner bins with better protection against the temperature effects of the cutting process. Depending on the regularity with which materials thicker than 110 mm are cut, consideration must be given to whether it would be advisable to cut thicker material on an auxiliary deck integrated in the inner bins.

Removing cut parts: the deck can be reinforced in such a way that the deck with the cut sheet can be moved by crane. In this manner, optimum service of the machine can be achieved!

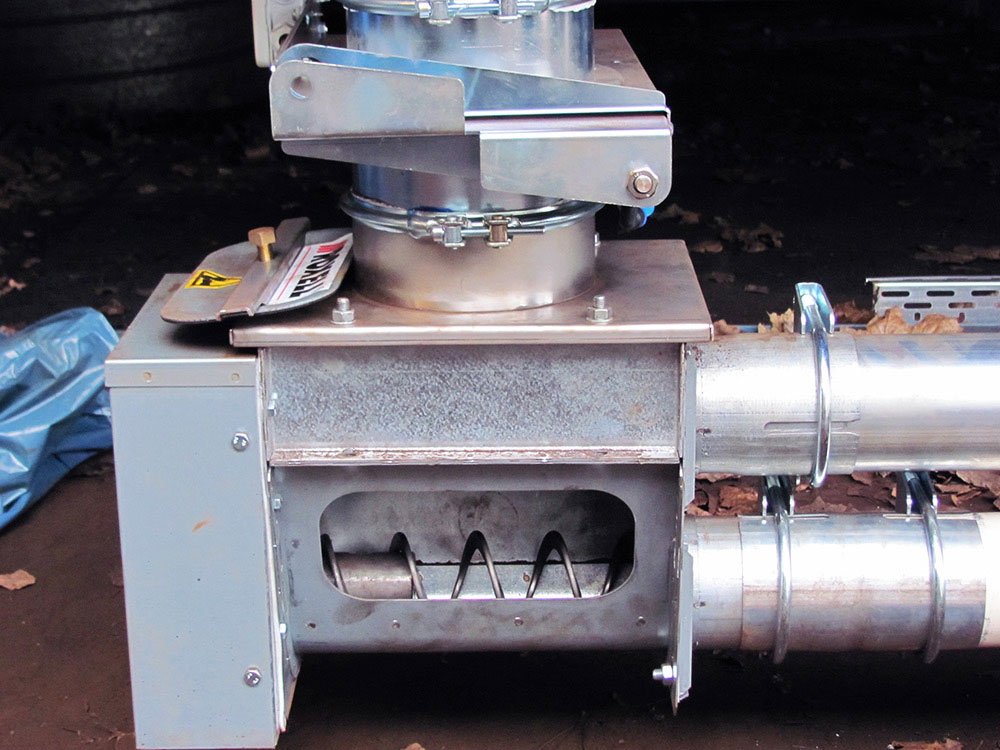

Cleaning

Optional grating in the extraction segments catch the small cutting parts, such that bulky waste and small cutting shapes remain within reach. The finer waste falls to the bottom of the extraction segments. Inner bins placed in the extraction segments provide for easy cleaning of the table and for better extraction: the waste falls on the bottom of these bins.

After the deck is removed, the inner bins containing the waste are hoisted out of the NOVODEK® end emptied over a central waste container. Cleaning of the NOVODEK® is fast and requires very little manpower.

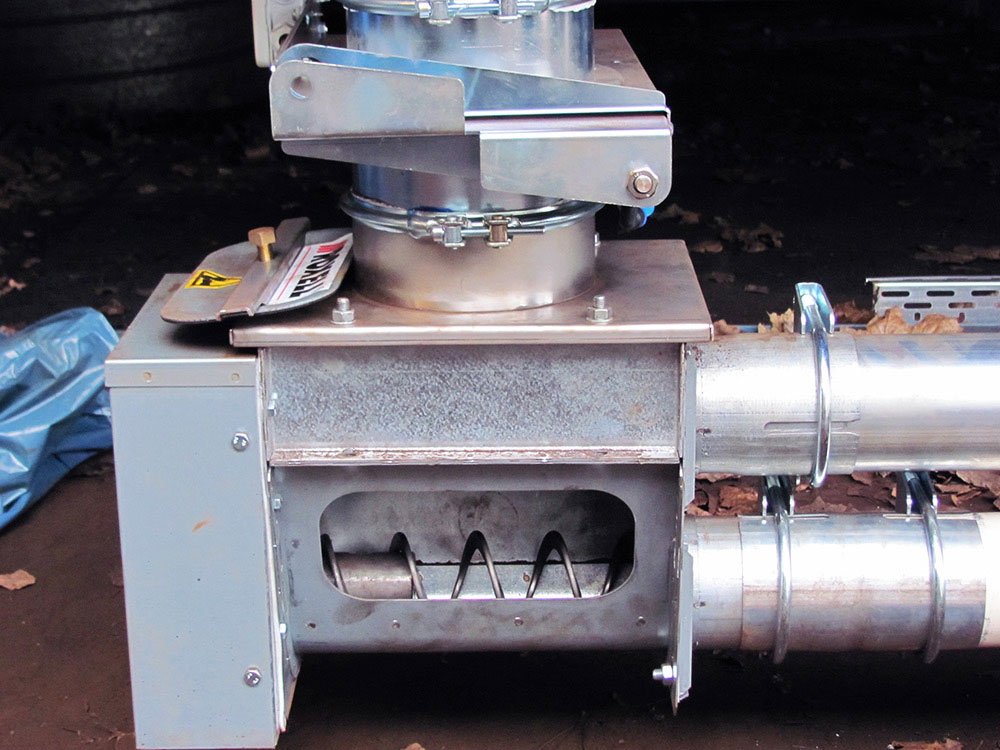

If the NOVODEK® has a conveyor, the basic section captures dust and gases, and the cutting residues and small pieces fall onto a steel sheet under the table. A conveying system then moves the waste and cutting parts over the bottom plate to the head end of the table.

The advantages: fast and easy collection of cutting parts; efficient removal of cutting residues; the cut products are protected against burnt-on cutting slag.

Cutting Thick Plates

To cut thick plates the NOVODEK® can be equipped with special inner bins in the segments to ensure longer tool life of the bottom plate. After cutting, the inner bins can be hoisted out of the segments and emptied above the bottom plate in one movement.

The cutting residues, which have cooled off by then, are subsequently transported to the head of the table by the conveyor.

Key Points

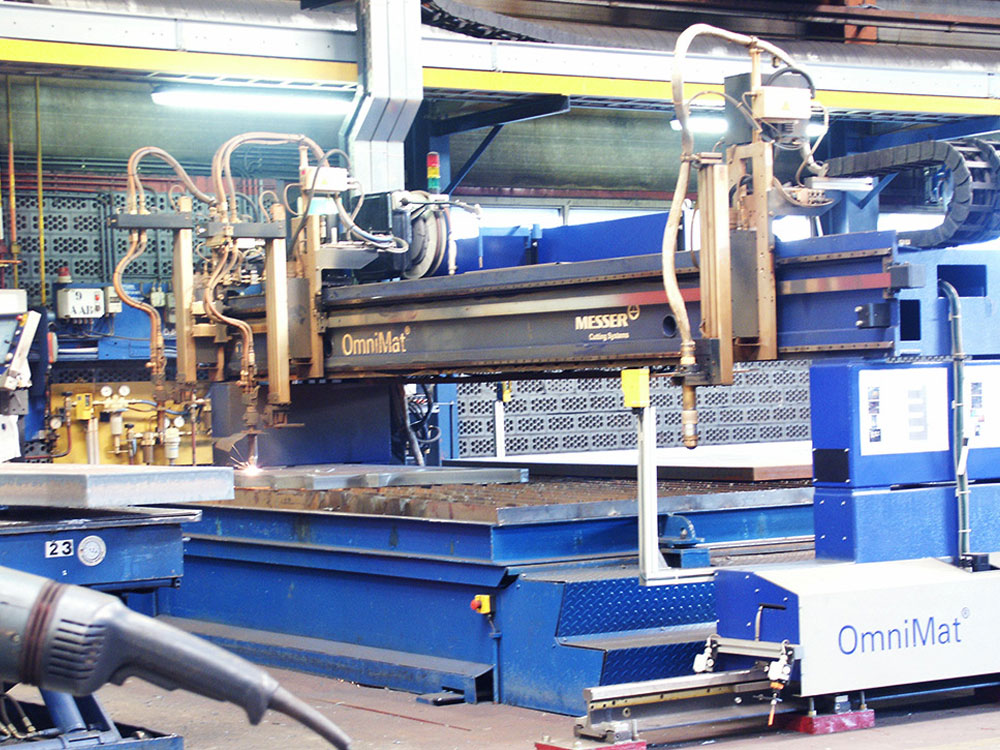

- Modular designed cutting table with bottom exhaust for the capture of dust and gases released in the different cutting processes (autogenous, plasma and laser).

- Suitable for cutting sheets up to 500 mm thick.

- Extraction per segment over the full width.

- Polluted air exhausted laterally to 1 or 2 discharge ducts.

- Removable deck with supporting strips to support the sheets to be cut.

- Reinforced deck suitable for moving by crane with the cut sheet.

- Inner bins in the extraction segments can be lifted out for easy cleaning of the table.

- Conveyor for removing small cutting parts and drosses from the bottom plate.

- Grating in extraction segments for catching small cutting parts.

- Suitable for all sheet sizes.

- Satisfies all Arbo [health and safety] standards.

Types

- NOVODEK® consisting of basic section and deck. Optional: reinforced deck, grating and inner bins.

- NOVODEK®-comfort consisting of basic section, deck and conveyor.